Dissertation: AI Powered Industrial Parts Classification System

"Machine learning is the automation of automation." - Lex Fridman

Introduction

Welcome to my Final Year Project (FYP) in industrial automation & robotics. I developed a machine learning algorithm using Python, TensorFlow, and Keras for classifying industrial parts as damaged, undamaged, or unrecognized.

User Requirements Specification (URS)

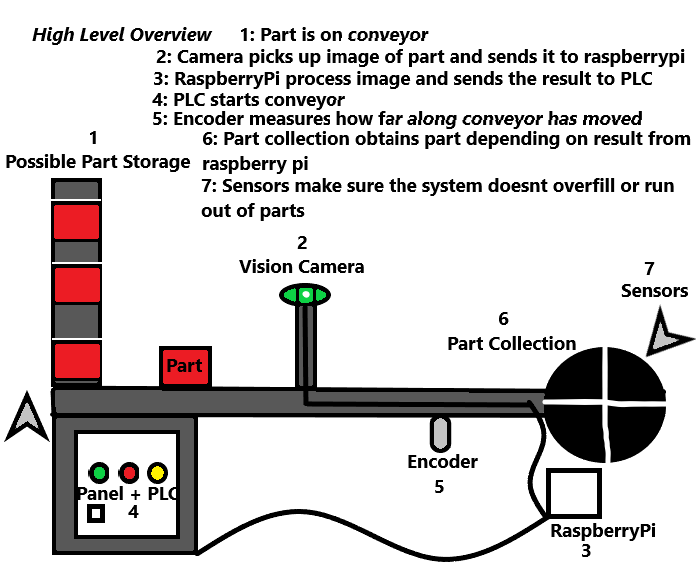

The URS outlines the goal: precise machine learning for classifying parts. Using Python, TensorFlow, and Keras, it integrates with Siemens S7 1200 PLC, Raspberry Pi 4, and a Cognex camera. Workflow involves parts on a servo-driven conveyor, captured by the camera for classification. Goals include accuracy, throughput, user interface, and maintenance.

Functional Design Specification (FDS)

The FDS details the system's functional architecture, ensuring accuracy with the URS. The algorithm, implemented in Python using TensorFlow and Keras, integrates with Siemens S7 1200 PLC, Raspberry Pi 4, and a Cognex camera. It emphasizes the algorithm's role in classifying parts, moving the conveyor, and communicating with the PLC. This document guides the development, acting as a blueprint.

My project aims to integrate machine learning into industrial automation, improving precision and reducing programming. The impact on industrial automation and robotics aligns with Industry 4.0. This represents a crucial step in my journey as a student, contributing to practical applications in the field of industrial automation and robotics engineering.